Share this

Increasing the speed of your DevOps teams

by Carl Weller on 28 March 2019

This is the third post in a series exploring Lean thinking and DevOps. In this post I cover one of the reasons work takes longer than it should.

For many years 'multi-tasking' has been touted as a virtue. We all do it, at an individual level throughout the day, and organisationally by assigning people to a mix of Business as Usual (BAU) and project work. Most organisations I work with have dozens (and in some cases hundreds) of projects on the go at any one time.

But there's a problem. Multi-tasking isn't good, and we generally don’t truly multi-task anyway. What people generally do is move items from "waiting" to "in progress" while they are focused on the task, and then back to "waiting" as they pick something else up. This tends to make delivery of any one item longer than it would if we worked in a sequential rather than parallel fashion.

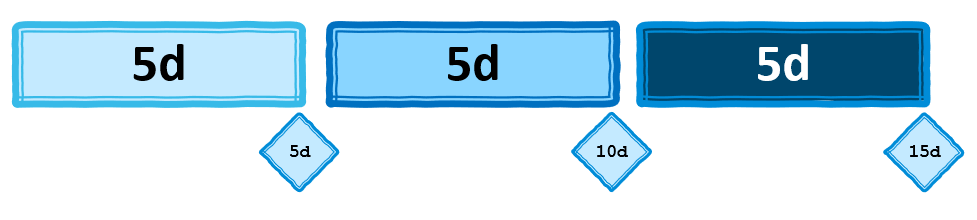

If we take the example of three simple tasks, each five days long, we can deliver them sequentially or in parallel. In series these items will be delivered every five days, so that’s a delivery on the 5th, 10th and 15th day respectively.

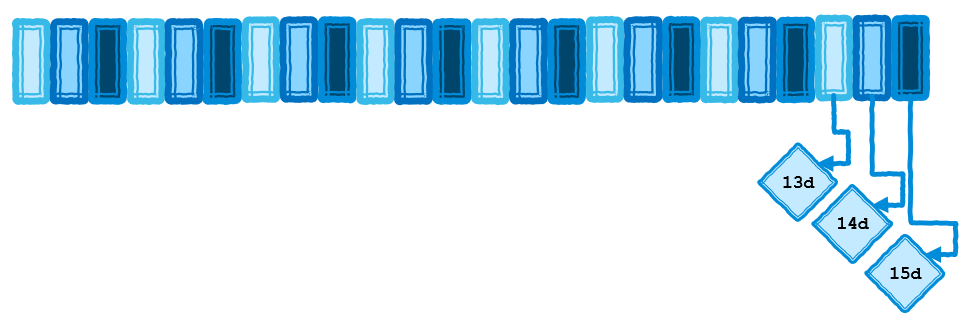

The worst case delivering them in parallel (i.e. 'multi-tasking') will result in delivering each item very close to the 15-day mark. And that's if we assume perfect efficiency and no productivity loss from context-switching. This is illustrated below.

In reality, each task may be delivered somewhat late, but in no case will two tasks be delivered on or before the 10th day.

This logic scales up and down your organisation – just as multi-tasking slows down one person with three simple tasks to do, multi-tasking with larger tasks or projects has the same issues at an organisational level.

Multi-tasking is a way of ensuring high utilisation when there are variable waits between work items due to dependencies. I'd say it is a hangover from 20th Century manufacturing techniques, except most successful manufacturers either use statistical process control to remove sources of variation or use some form of synchronising mechanism to manage small variations (e.g. Eli Goldratt's Theory of Constraints or Toyota's Just-in-Time process).

By trying to do more you are going slower. This was proven by John Little in the early 1960s and is known in operations management and Agile circles as "Little's Law".

Little's Law is foundational in queuing theory and is used in the allocation of toll-booths on new highways, in designing computer chips, in fact anything where there is a flow of incoming work, one or more in-progress states, and a way for work to leave the 'system'. For those who are interested in researching this further here's a useful paper by Mr Little himself. Be aware it does get a little bit geeky in places.

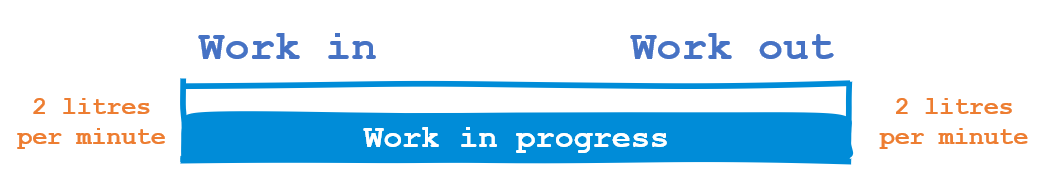

An easy way to think about this is to visualise water flowing through a pipe. The most efficient process would be one where the water is entering and departing the pipe at the same rate (i.e. very low 'work in progress').

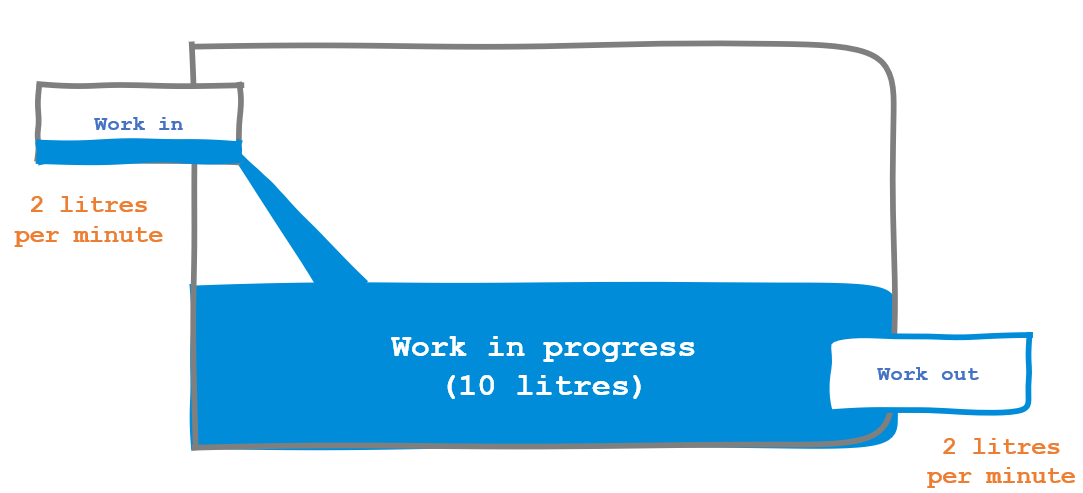

However, what typically happens in knowledge working organisations is that we allow more work to enter the system than is leaving. One of the reasons for this is we have no useful ways of seeing how full the work system is. Most of the work in sitting in people's heads (or on hard-drives). Its not like an airport where, if more planes arrived than departed, you would start to see issues very quickly and then act to resolve them. Let's imagine we add a storage tank to our pipe to show where work sits while its waiting to be done.

Using Little's Law we know the throughput (2 litres per minute) and we know the work in progress (10 litres). From this we can calculate that on average every work item (why not think of them as cups of water?) will take 5 minutes. The formula here is that average completion time = work in progress divided by throughput.

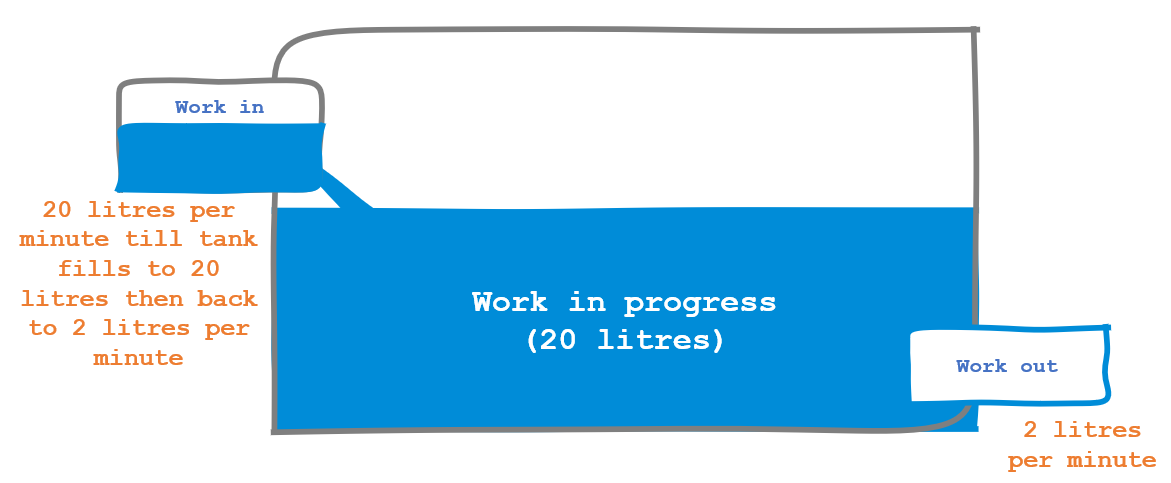

If we allow even more work to enter the system then we need a bigger storage tank. Let's say we allow another 10 litres of water in (even though we are still only getting through 2 litres of work every minute).

Once the work system stabilises again, we can re-calculate average time to completion (Little's Law assumes a stable work system). In this case the average time to completion is now 10 minutes. That is: 20 litres divided by 2 litres per minute. The worst thing is, many organisations find that things start taking longer so they start them earlier! This adds more work in progress and makes the problem worse rather than better.

So, the more work in progress you have the longer everything takes. Now think about your in-flight projects. Each one of those is not a matter of minutes.

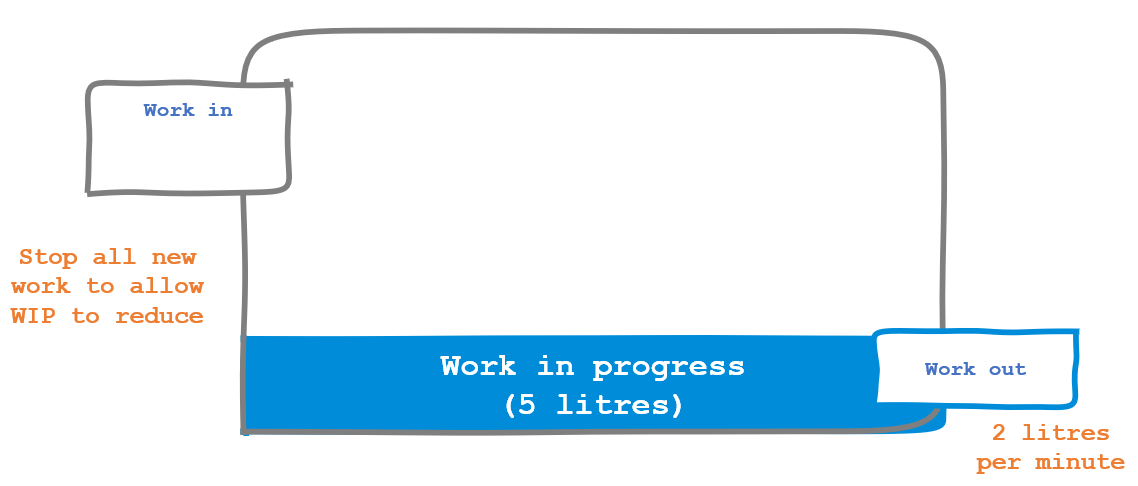

If we stop any new work entering the system until work in progress is down to 5 litres, then average time to completion will drop to 2.5 minutes. We are now much more responsive. If these are short projects instead of cups of water, it would give us the opportunity to quickly change direction as required by our customers.

And the most magical thing about this? Allowing work to enter the system is a policy decision. It is much easier to make such a management call than it is for people to learn how to work twice as fast (i.e. change the "work out" volume to 4 litres per minute).

Turning off the "on tap" is the fastest way to reduce work in progress and start seeing the average time to completion drop. If this is too much, then try to reduce incoming work, but remember, for work in progress to go down more work has to be leaving the system than is entering the system.

So how do I start implementing this approach?

Well, my first post in this series, Introducing Lean thinking to DevOps, has information on creating a pull system and using work in progress limits. My second post in this series, How Lean can help DevOps teams be more responsive, covers how you might use a priority-setting meeting to continually replenish the input area of a team board.

Both posts use visual workflow boards. These can be physical or virtual (e.g. Trello, Jira, Azure DevOps). To be quite frank, a virtual board can vanish from sight on a hard-drive pretty easily and simply become a team workflow management tool rather than a highly visual way of communicating with stakeholders, so I prefer physical boards.

If you need to run a virtual board for offsite team members, please consider using a physical board as well. It will provide the level of transparency you need to get your work system under control. It will also help discussions with stakeholders about adding more work. Try having those conversations in front of your physical work board!

You will need to use some political capital to get stakeholders to try this approach as it is counter to the way knowledge working organisations tend to think about work.

In a future post I'll look at value adding and non-value adding work.

If you like these posts and/or would like to know more, please use the comments section below.

Share this

- Agile Development (89)

- Software Development (68)

- Scrum (41)

- Agile (32)

- Business Analysis (28)

- Application Lifecycle Management (27)

- Capability Development (23)

- Requirements (21)

- Lean Software Development (20)

- Solution Architecture (19)

- DevOps (17)

- Digital Disruption (17)

- Project Management (17)

- Coaching (16)

- IT Professional (15)

- IT Project (15)

- Knowledge Sharing (13)

- Equinox IT News (12)

- Agile Transformation (11)

- IT Consulting (11)

- Digital Transformation (10)

- Strategic Planning (10)

- IT Governance (9)

- International Leaders (9)

- People (9)

- Change Management (8)

- Cloud (8)

- MIT Sloan CISR (7)

- Working from Home (6)

- Azure DevOps (5)

- Innovation (5)

- Kanban (5)

- Business Architecture (4)

- Continuous Integration (4)

- Enterprise Analysis (4)

- Client Briefing Events (3)

- GitHub (3)

- IT Services (3)

- AI (2)

- Business Rules (2)

- Communities of Practice (2)

- Data Visualisation (2)

- Java Development (2)

- Lean Startup (2)

- Scaling (2)

- Security (2)

- System Performance (2)

- ✨ (2)

- Automation (1)

- FinOps (1)

- Microsoft Azure (1)

- Satir Change Model (1)

- Testing (1)

- March 2025 (1)

- December 2024 (1)

- August 2024 (1)

- February 2024 (3)

- January 2024 (1)

- September 2023 (2)

- July 2023 (3)

- August 2022 (4)

- July 2021 (1)

- March 2021 (1)

- February 2021 (1)

- November 2020 (2)

- July 2020 (1)

- June 2020 (2)

- May 2020 (3)

- March 2020 (3)

- August 2019 (1)

- July 2019 (2)

- June 2019 (1)

- April 2019 (3)

- March 2019 (2)

- December 2018 (1)

- October 2018 (1)

- August 2018 (1)

- July 2018 (1)

- April 2018 (2)

- February 2018 (1)

- January 2018 (1)

- September 2017 (1)

- July 2017 (1)

- February 2017 (1)

- January 2017 (1)

- October 2016 (2)

- September 2016 (1)

- August 2016 (4)

- July 2016 (3)

- June 2016 (3)

- May 2016 (4)

- April 2016 (5)

- March 2016 (1)

- February 2016 (1)

- January 2016 (3)

- December 2015 (5)

- November 2015 (11)

- October 2015 (3)

- September 2015 (2)

- August 2015 (2)

- July 2015 (7)

- June 2015 (7)

- April 2015 (1)

- March 2015 (2)

- February 2015 (2)

- December 2014 (3)

- September 2014 (2)

- July 2014 (1)

- June 2014 (2)

- May 2014 (8)

- April 2014 (1)

- March 2014 (2)

- February 2014 (2)

- November 2013 (1)

- October 2013 (2)

- September 2013 (2)

- August 2013 (2)

- May 2013 (1)

- April 2013 (3)

- March 2013 (2)

- February 2013 (1)

- January 2013 (1)

- November 2012 (1)

- October 2012 (1)

- September 2012 (1)

- July 2012 (2)

- June 2012 (1)

- May 2012 (1)

- November 2011 (2)

- August 2011 (2)

- July 2011 (3)

- June 2011 (4)

- April 2011 (2)

- February 2011 (1)

- January 2011 (2)

- December 2010 (1)

- November 2010 (1)

- October 2010 (1)

- February 2010 (1)

- July 2009 (1)

- October 2008 (1)